Wholesale Discount for The Production of Microelectronic Devices Copper Flake Powder

We normally think and practice corresponding towards the change of circumstance, and grow up. We aim at the achievement of a richer mind and body plus the living for Wholesale Discount for The Production of Microelectronic Devices Copper Flake Powder, We’ve been also regularly wanting to establish relationship with new suppliers to supply ground breaking and intelligent option to our valued clients.

We normally think and practice corresponding towards the change of circumstance, and grow up. We aim at the achievement of a richer mind and body plus the living for China Copper Powder and Electrolytic Copper Powder, Since the establishment of our company, we now have realized the importance of providing good quality items and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question factors they do not understand. We break down those people barriers to ensure you get what you want to the level you expect, when you want it.

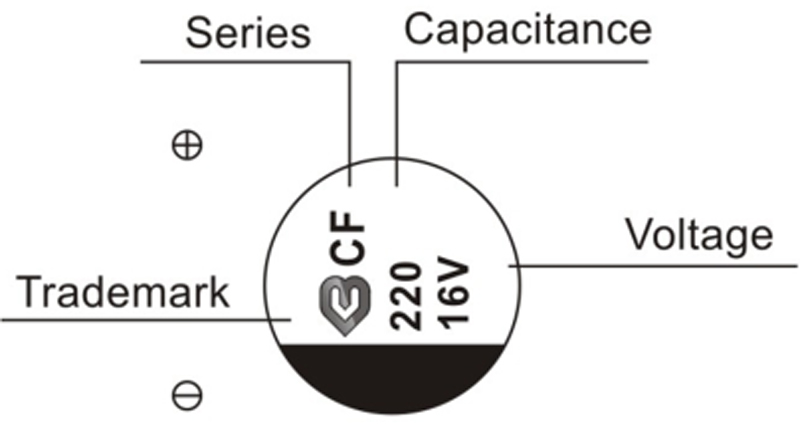

Specifications

| Items | Characteristics | ||

| CategoryTemperature Range | -55 ~ +105℃ | ||

| Rated Voltage Range | 2.5 ~ 25V | ||

| Capacitance tolerance | ±20%(M) (at 20℃,120Hz) | ||

| Leakage Current | After 2 minutes applied for rated voltage at 20℃, less than or equal to the specified value. | ||

| Dissipation Factor | Rated voltage (V) | 2.5~25 | (at 20℃,120Hz) |

| tanδ (Max.) | 0.12 | ||

| Low TemperatureCharacteristics(Max.Impedance Ratio) | Z(-25℃)/Z(+20℃) | ≤1.25 | (100KHz) |

| Z(-55℃)/Z(+20℃) | ≤1.25 | ||

| Endurance | The specifications listed below shall be met when the capacitors are restored to 20°C after the rated voltage is applied for 3000 hours at 105℃. | ||

| Appearance | No significant damage | ||

| Capacitance change | ≦±20% of the initial value | ||

| D.F.(tanδ) | ≦150% of the specified value | ||

| ESR | ≦150% of the specified value | ||

| Leakage current | ≦The specified value | ||

| Damp Heat (Steady State) |

The specifications listed below shall be met when the capacitors are restored to 20°C after the rated voltage is applied for 1000 hours at 60℃, 90%~ 95% RH. | ||

| Appearance | No significant damage | ||

| Capacitance change | ≦±20% of the initial value | ||

| D.F.(tanδ) | ≦150% of the specified value | ||

| ESR | ≦150% of the specified value | ||

| Leakage current | ≦The specified value | ||

| Surge Voltage | Surge Voltage=Rated voltage * 1.15(V)The capacitors shall be subjected to 1000 cycles each consisting of charge with the surge voltages specified at 105℃ for 30 seconds through a protective resistor (Rc=1kΩ) and discharge for 5 minutes 30 seconds | ||

| Appearance | No significant damage | ||

| Capacitance change | ≦±20% of the initial value | ||

| D.F.(tanδ) | ≦150% of the specified value | ||

| ESR | ≦150% of the specified value | ||

| Leakage current | ≦The specified value | ||

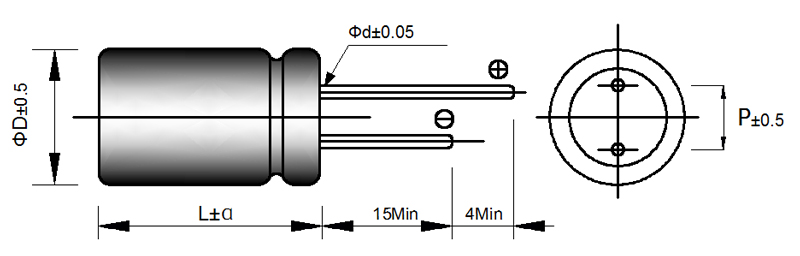

Dimensions (mm)

|

ΦD |

5 |

6.3 |

8 |

10 |

|

P |

2 |

2.5 |

3.5 |

5 |

|

Φd |

0.5 |

0.5 |

0.6 |

0.6 |

|

ɑ |

L<16mm:1.0 |

|||

|

L≧16mm:2.0 |

||||

Standard Ratings

|

Rated voltage (V) |

Rated capacitance(uF) |

Case size |

ESR(mΩ)at 20℃,100 KHz |

Rated ripple carrent (mArms/105℃/100kHz) |

|

2.5 |

330 |

5*7 |

18 |

2690 |

|

470 |

5*7 |

18 |

2690 |

|

|

560 |

6.3*8 |

18 |

2690 |

|

|

680 |

6.3*8 |

18 |

2690 |

|

|

4 |

220 |

5*7 |

18 |

2690 |

|

330 |

5*7 |

18 |

2690 |

|

|

470 |

6.3*8 |

18 |

2690 |

|

|

560 |

6.3*8 |

18 |

2690 |

|

|

6.3 |

220 |

5*7 |

18 |

2500 |

|

330 |

5*7 |

18 |

2500 |

|

|

330 |

6.3*8 |

16 |

2900 |

|

|

470 |

6.3*8 |

16 |

2900 |

|

|

560 |

6.3*8 |

16 |

3100 |

|

|

680 |

6.3*8 |

16 |

3100 |

|

|

10 |

100 |

5*7 |

18 |

2690 |

|

150 |

5*7 |

18 |

2690 |

|

|

270 |

6.3*8 |

16 |

4100 |

|

|

330 |

6.3*8 |

16 |

4100 |

|

|

16 |

100 |

5*7 |

20 |

2690 |

|

100 |

6.3*8 |

18 |

2900 |

|

|

220 |

6.3*8 |

16 |

2900 |

|

|

25 |

22 |

5*7 |

45 |

2670 |

|

33 |

5*7 |

40 |

2670 |

|

|

33 |

6.3*8 |

40 |

2900 |

|

|

47 |

6.3*8 |

40 |

2900 |

Rated Ripple Current Coefficient

|

Frequency (Hz) |

120Hz≤f<1kHz |

1kHz≤f<10kHz |

10kHz≤f<100kHz |

100kHz≤f<500kHz |

| Coefficient |

0.05 |

0.30 |

0.70 |

1.00 |

We normally think and practice corresponding towards the change of circumstance, and grow up. We aim at the achievement of a richer mind and body plus the living for Wholesale Discount for The Production of Microelectronic Devices Copper Flake Powder, We’ve been also regularly wanting to establish relationship with new suppliers to supply ground breaking and intelligent option to our valued clients.

Wholesale Discount China Copper Powder and Electrolytic Copper Powder, Since the establishment of our company, we now have realized the importance of providing good quality items and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question factors they do not understand. We break down those people barriers to ensure you get what you want to the level you expect, when you want it.